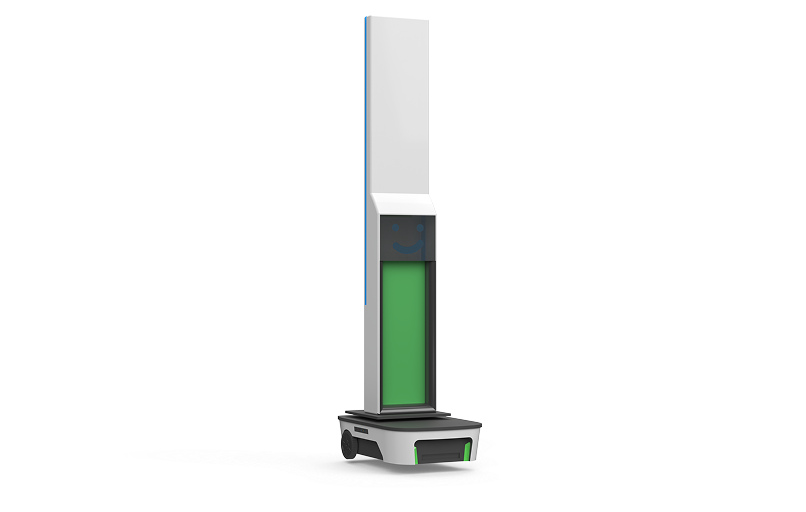

duketag Smart AGV

Smart Automation for Seamless Warehousing!

Our Duketag Smart AGV automates warehouse operations by tracking inventory in real-time using RFID and LiDAR. It updates stock counts, feeds live data into SAPs, and reduces manual effort. Ideal for high-volume warehouses, it enhances accuracy, visibility, and efficiency across complex supply chains.

Automated

Restocking Alerts

Operation

Adv. Lidar

Navigation

Automated

inventory Record

Self Charging &

Resting Stations

Live inventory

with location to

Mobile Phone

Our Edge

Why duketag !?

We optimize the work processes with integrated roller conveyor systems for distribution

- Comprehensive automation solutions covering material handling and asset tracking.

- AI-driven analytics to optimize warehouse workflows

- Custom conveyor automation integrated with intelligent tracking

- Adaptable technology infrastructure

- Industrial IoT connectivity for real-time cloud-based monitoring and control.

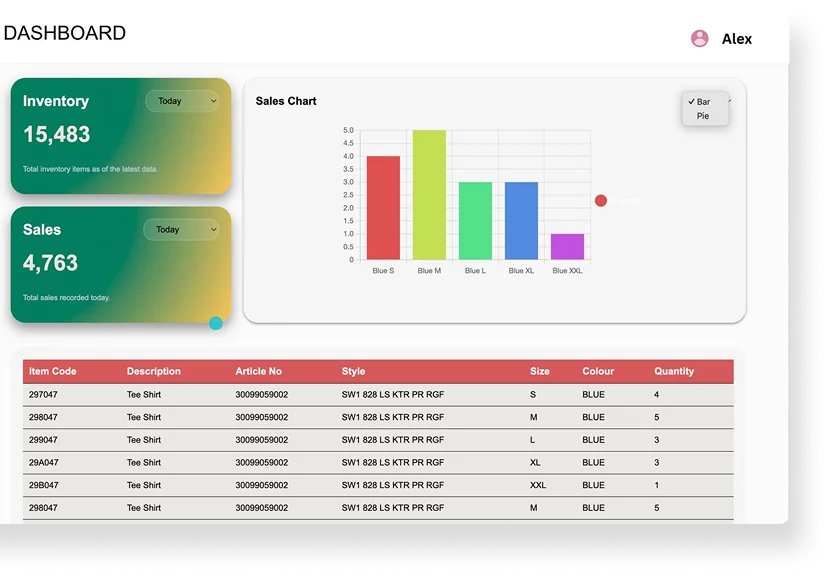

Nex-Gen Softaware

Our proprietary software platform transformscomplex data into actionable insights

- Real-time inventory tracking across warehouse zones and transit points

- Adv. EPC Processing for optimised database management

- Cloud-based architecture ensuring centralized data.

- Seamless WMS/ERP integration

ReadPoint.

Our Seamless RFID

Monitoring Software

Our Duketag proprietary software ecosystem transforms complex EPC data into real-time insights. With seamless ERP integration and precise inventory tracking, it delivers full visibility, accountability, and control across your supply chain—empowering smarter, faster decisions from inbound to outbound.

Automated Inventory Counting

Scan While You Roll

Mounted on AGVs, RFID readers scan tagged items while moving, enabling autonomous and accurate inventory counts without stopping operations.

1/2Dynamic Location Tracking

Real-Time Movement Intelligence

Provides continuous tracking of goods and materials as AGVs navigate the facility. Supports real-time location awareness and logistics optimization.

2/2