duketag Gate

Effortless Tracking - Automate Every Entry & Exit!

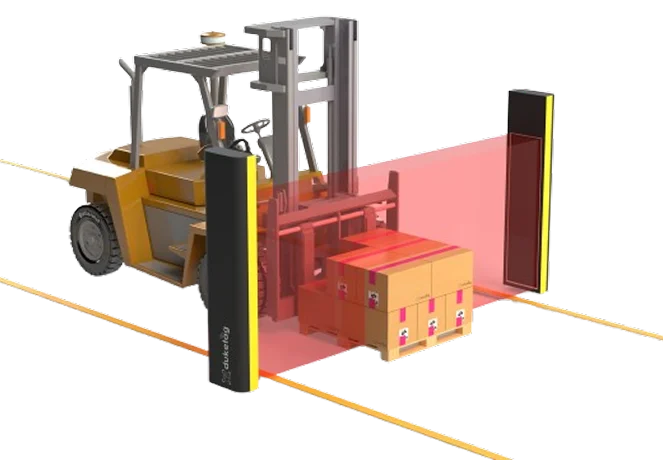

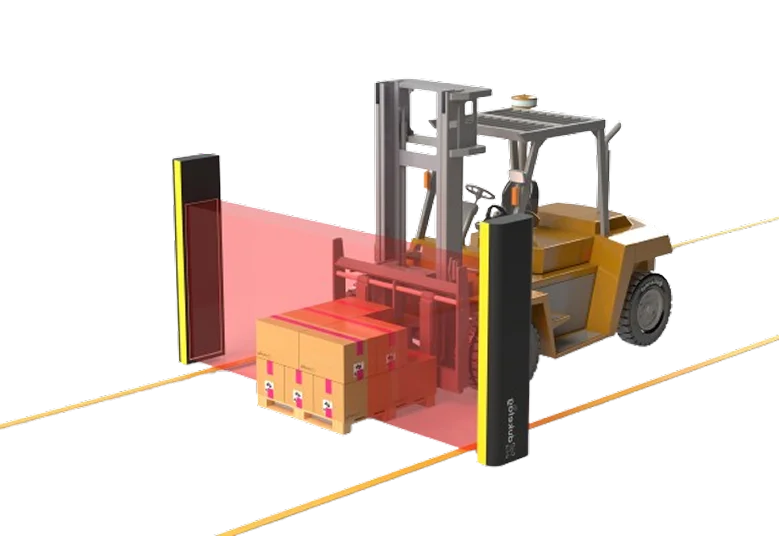

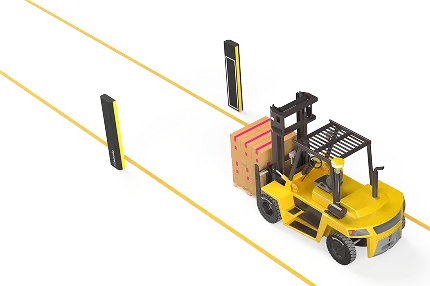

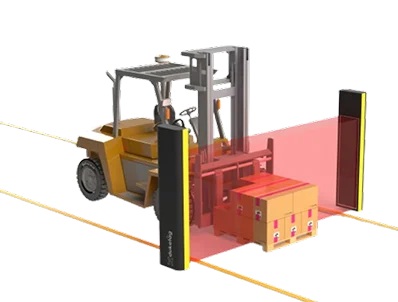

The duketag RFID Gate System automates inventory tracking at entry and exit points, ensuring realtime visibility without manual effort. Using high-precision RFID antennas, it scans tagged assets instantly, eliminating delays, errors, and security risks. Ideal for warehouses and logistics hubs, it enhances workflow automation, loss prevention, and operational control.

Entry/Exit

Employee Attendance & Security

Directional

Monitoring

Hands Free

& Fast Operation

Tamper Detection

Tamper Detection

Dock Door at Truck

loading/ unloading

Bulk Movement

Tracking

Our Edge

Why duketag !?

We optimize the work processes with integrated roller conveyor systems for distribution

- Comprehensive automation solutions covering material handling and asset tracking.

- AI-driven analytics to optimize warehouse workflows

- Custom conveyor automation integrated with intelligent tracking

- Adaptable technology infrastructure

- Industrial IoT connectivity for real-time cloud-based monitoring and control.

Nex-Gen Softaware

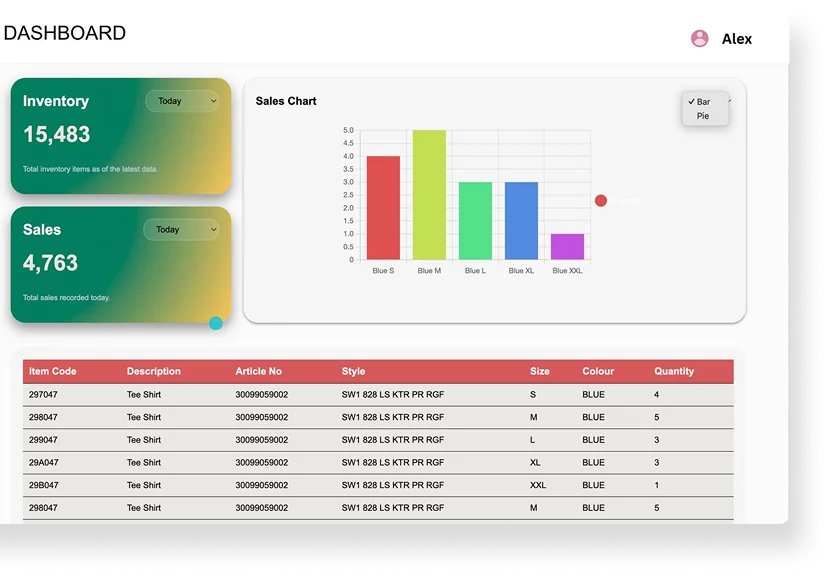

Our proprietary software platform transformscomplex data into actionable insights

- Real-time inventory tracking across warehouse zones and transit points

- Adv. EPC Processing for optimised database management

- Cloud-based architecture ensuring centralized data.

- Seamless WMS/ERP integration

ReadPoint.

Our Seamless RFID

Monitoring Software

Our Duketag proprietary software ecosystem transforms complex EPC data into real-time insights. With seamless ERP integration and precise inventory tracking, it delivers full visibility, accountability, and control across your supply chain—empowering smarter, faster decisions from inbound to outbound.

Entry/Exit Control

Every Entry Tracked. Every Exit Logged.

Authorizes and monitors personnel and goods at entry and exit points. Ensures secure zone access and audit-ready movement history.

1/3Asset Movement Tracking

Know Where Everything Goes

Tracks tools, machines, and movable assets as they move within or beyond defined zones—providing real-time visibility and loss prevention.

2/3Employee & Equipment Monitoring

Smarter Visibility on the Floor

Monitors workforce and equipment location in real-time to optimize workflows, enforce safety zones, and improve operational efficiency.

3/3