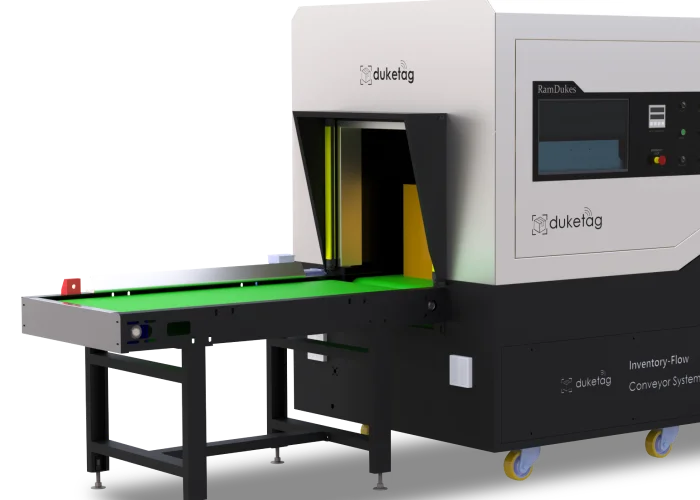

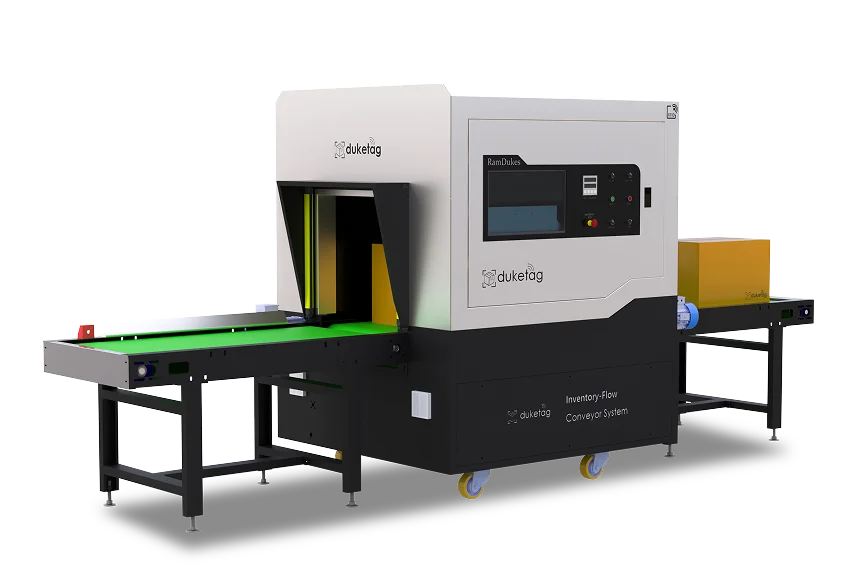

duketag Tunnel Station

Precision & Power for High-Volume Operations

Our duketag Tunnel Station delivers high-speed, error-free bulk RFID scanning—perfect for warehouses and production lines. With advanced shielding and powerful antennas, it ensures precise reads, streamlines operations, cuts manual effort, and integrates effortlessly with existing systems. Built for reliability, it empowers real-time tracking and smarter supply chain management.

Adv.

Shielding

Weight

Measurement

Bulk Packing

at each process

Report

>ERP

Less than

procesing time on each box

Accuracy

Multi-item

processing

IPC/

Monitor

Our Edge

Why duketag !?

We optimize the work processes with integrated roller conveyor systems for distribution

- Comprehensive automation solutions covering material handling and asset tracking.

- AI-driven analytics to optimize warehouse workflows

- Custom conveyor automation integrated with intelligent tracking

- Adaptable technology infrastructure

- Industrial IoT connectivity for real-time cloud-based monitoring and control.

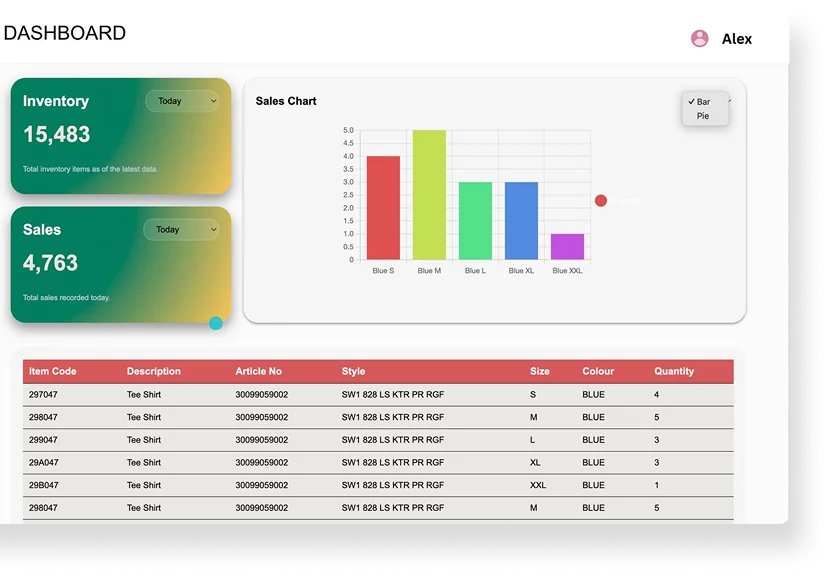

Nex-Gen Softaware

Our proprietary software platform transformscomplex data into actionable insights

- Real-time inventory tracking across warehouse zones and transit points

- Adv. EPC Processing for optimised database management

- Cloud-based architecture ensuring centralized data.

- Seamless WMS/ERP integration

ReadPoint.

Our Seamless RFID

Monitoring Software

Our Duketag proprietary software ecosystem transforms complex EPC data into real-time insights. With seamless ERP integration and precise inventory tracking, it delivers full visibility, accountability, and control across your supply chain—empowering smarter, faster decisions from inbound to outbound.

Outward Verification

Ensure Accuracy Before Dispatch

The Tunnel Station verifies every outbound item in real-time, cross-checking against dispatch records to eliminate shipping errors. This ensures only the correct goods leave the facility, reducing returns and improving customer satisfaction.

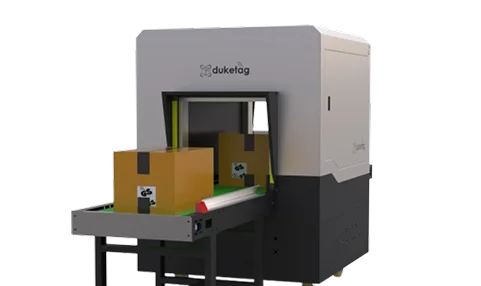

1/3Inward Goods Scanning

Instant Logging at Arrival

As goods enter the warehouse, the Tunnel Station automatically scans and records all items—no manual intervention required. It accelerates the receiving process while maintaining accurate inventory updates.

2/3Warehouse Inventory Audits

Fast Counts. Zero Downtime.

The Tunnel Station verifies every outbound item in real-time, cross-checking against dispatch records to eliminate shipping errors. This ensures only the correct goods leave the facility, reducing returns and improving customer satisfaction.

3/3